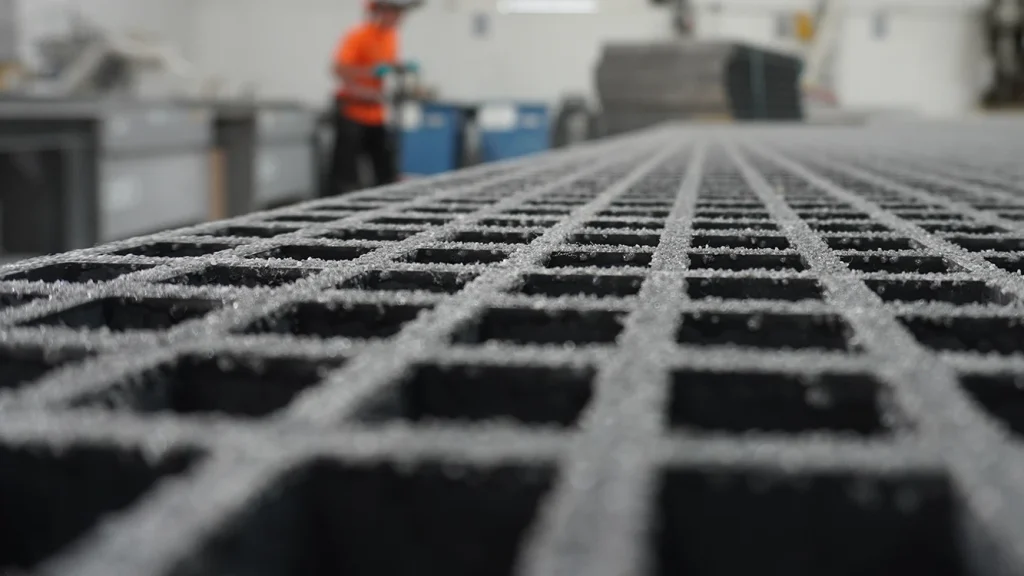

GRP Grating: The Ultimate Lightweight and Durable Flooring Solution

Introduction

In today’s industrial and commercial environments, choosing the right flooring system is crucial for safety, durability, and long-term performance. GRP Grating has rapidly gained recognition as one of the most reliable, cost-effective, and versatile flooring solutions available. Its combination of exceptional strength, lightweight properties, corrosion resistance, and minimal maintenance requirements makes it an ideal choice across a wide range of industries. This article explores everything you need to know about GRP Grating, including its features, benefits, applications, installation considerations, and why it outperforms traditional materials such as steel or timber.

What Is GRP Grating?

Understanding the Material

GRP Grating—Glass Reinforced Plastic Grating—is a high-strength composite material composed of glass fibers and resin. The fusion of these materials creates a robust, lightweight, and highly durable structure suitable for challenging environments. Unlike metal grating, GRP Grating does not corrode, rust, or conduct electricity, making it a preferred option for industries requiring enhanced safety and reliability.

Types of GRP Grating

GRP Grating is available in two primary types:

1. Moulded GRP Grating

This type is made by placing fiberglass into a mould and saturating it with resin. The result is a uniform, non-directional grating with exceptional load-bearing properties.

2. Pultruded GRP Grating

Pultruded GRP Grating is manufactured by pulling continuous glass fibers through a resin bath and then forming them into structural shapes. This process creates grating with higher unidirectional strength—ideal for environments requiring extreme load resistance.

Key Features of GRP Grating

Exceptional Durability

One of the standout features of GRP Grating is its long lifespan. Resistant to corrosion, impact, and weathering, it performs reliably for decades even in harsh environments such as offshore platforms, chemical plants, and wastewater facilities.

Lightweight Structure

Despite being incredibly strong, GRP Grating is remarkably lightweight. This makes transportation, handling, and installation significantly easier compared to steel or concrete flooring systems.

Anti-Slip Surface

Most GRP Grating is designed with a gritted anti-slip surface, ensuring superior traction even in wet, oily, or hazardous conditions. This feature dramatically reduces workplace accidents and improves operational safety.

Corrosion and Chemical Resistance

The resin matrix in GRP Grating provides high resistance to chemicals, acids, and corrosive materials—an essential attribute for industrial environments where chemical exposure is common.

Electrical and Thermal Non-Conductivity

Because GRP Grating is non-conductive, it minimizes electrical hazards. This makes it ideal for electrical substations, power plants, and other facilities where safety is a priority.

Fire Retardant Properties

High-quality GRP Grating is available with fire-retardant resins that comply with international fire safety standards. This ensures optimal performance even in hazardous or high-temperature environments.

Benefits of Using GRP Grating

Cost-Effectiveness

Although the initial cost of GRP Grating might be higher than timber or certain metal alternatives, its long-term value far outweighs the initial investment. Its durability, low maintenance requirements, and corrosion resistance result in significant long-term cost savings.

Minimal Maintenance

Unlike steel grating, GRP Grating does not require regular painting, galvanizing, or rust removal. Simple routine cleaning is sufficient to maintain its performance and appearance.

Enhanced Safety

With its non-slip surface, fire resistance, and non-conductive properties, GRP Grating contributes to safer working conditions—reducing risks and improving compliance with safety regulations.

Versatility

GRP Grating can be used across an impressive variety of applications, from industrial platforms to pedestrian walkways. Its compatibility with different surfaces and environments makes it one of the most versatile flooring options on the market.

Long-Term Performance

Due to its superior resistance to wear and environmental damage, GRP Grating continues to perform exceptionally well for many years, even under heavy loads or harsh environmental exposure.

Applications of GRP Grating

Industrial Applications

Chemical Plants

The corrosion resistance of GRP Grating makes it ideal for areas with frequent exposure to chemicals and corrosive liquids.

Petrochemical Facilities

In petrochemical plants, GRP Grating provides a safe and durable flooring option that withstands heavy loads and hazardous conditions.

Power Stations

The non-conductive nature of GRP Grating enhances safety in electrical environments, reducing the risk of electric shock.

Marine and Offshore Applications

GRP Grating is widely used on offshore platforms, ship decks, and docks due to its exceptional resistance to saltwater, moisture, and extreme weather conditions.

Water Treatment Plants

Its resistance to moisture, algae growth, and chemicals makes GRP Grating a top choice for wastewater facilities, filtration systems, and treatment plants.

Commercial and Public Areas

In commercial settings such as parks, pedestrian bridges, and public walkways, GRP Grating provides a safe, non-slip, and aesthetically pleasing surface.

Transportation and Infrastructure

For railway stations, airports, and industrial walkways, GRP Grating offers durable, lightweight flooring that supports heavy foot traffic and equipment.

Installation Considerations for GRP Grating

Choosing the Right Size and Thickness

Selecting the appropriate size and thickness of GRP Grating depends on load requirements, environmental conditions, and intended use. Proper evaluation ensures maximum safety and performance.

Support Structure Requirements

The support structure must be compatible with the chosen grating type. While GRP Grating is lightweight, it still requires adequate support to maintain load capacity.

Fastening and Fixing Systems

Proper fixing is essential to prevent movement or uplift. High-quality clips and clamps designed specifically for GRP Grating should be used during installation.

Surface Preparation

Prior to installation, ensure that the underlying structure is clean, level, and structurally sound. This helps optimize the lifespan and effectiveness of the GRP Grating.

Why GRP Grating Outperforms Traditional Materials

vs. Steel Grating

Steel is strong but prone to rust, corrosion, and electrical conductivity. GRP Grating eliminates these issues while delivering comparable strength at a fraction of the weight.

vs. Timber

Timber absorbs moisture, warps over time, and requires regular maintenance. GRP Grating provides long-lasting performance without susceptibility to rot, insects, or decay.

vs. Concrete

Concrete is heavy and difficult to install or modify. GRP Grating offers a lightweight option that is easier to install and requires minimal maintenance.

Environmental Advantages of GRP Grating

Sustainable and Long-Lasting

The long lifespan of GRP Grating reduces the need for frequent replacements, contributing to a more sustainable industry practice.

Energy-Efficient Production

Compared to metal manufacturing processes, producing GRP Grating often requires less energy, further improving its environmental footprint.

Recyclability

Many types of GRP Grating can be recycled, making them an eco-friendly choice for organizations looking to minimize waste.

Tips for Selecting the Best GRP Grating for Your Needs

Identify Environmental Conditions

Understanding the specific conditions—such as chemical exposure, temperature extremes, or load capacity—helps you choose the most effective GRP Grating type.

Work With a Trusted Supplier

Choosing a reputable supplier ensures that your GRP Grating meets industry standards and includes reliable warranties or support.

Consider Surface Finish Options

Different environments may require varying levels of slip resistance. Selecting the right surface finish enhances safety and performance.

Evaluate Long-Term Costs

While the upfront cost is important, focus on long-term savings. GRP Grating provides excellent value through reduced maintenance and extended lifespan.

FAQs About GRP Grating

What Makes GRP Grating a Lightweight Yet Strong Flooring Option?

GRP Grating is manufactured using high-strength fibreglass, offering excellent load capacity while remaining significantly lighter than steel. This combination ensures easier handling and long-term structural performance.

How Does GRP Grating Perform Compared to Traditional Metal Flooring?

Unlike metal, GRP Grating does not corrode, rust, or warp in harsh environments. It provides superior durability with minimal maintenance requirements.

Is GRP Grating Suitable for High-Traffic Industrial Areas?

Yes, GRP Grating is designed to withstand heavy foot traffic, equipment loads, and continuous use. Its anti-slip surface enhances safety in demanding industrial settings.

Conclusion

GRP Grating stands out as one of the most effective, durable, and versatile flooring solutions available today. With its combination of strength, corrosion resistance, lightweight structure, and enhanced safety features, it consistently outperforms traditional materials like steel, timber, and concrete. Whether used in industrial facilities, marine environments, public areas, or water treatment plants, GRP Grating offers a reliable and long-lasting solution that requires minimal maintenance and delivers excellent long-term value. As businesses continue to prioritize safety, efficiency, and sustainability, GRP Grating remains the ultimate choice for modern flooring applications.